A GREAT TRADITION PROJECTED IN THE FUTURE:

FOR 200 YEARS MASTERS OF STEEL IN ITALY

In the valley that stretches between the ancient cities of Camerino and Fabriano, surrounded by the high mountains of the central Italian Apennines, metal processing has been a traditional activity since the Middle Ages: the harshness of the territory, not very suitable for agriculture, the abundance of wood for fire and water, natural elements then indispensable for the processing of metals have in fact favored the growth of a flourishing artisan activity in the sector.

We of the GPS INOX, generation after generation, for two hundred years have been working steel. Today many things have changed compared to the past: the products and the technology used have changed, but the passion for steel and the craftsmanship of the work, based on the ability and skill of all employees, from designers to workshop workers , remain the same as ever and allow us, today as yesterday, to give a steel shape to our customers' wishes.

Strengthened by our experience and tradition in the processing of steel, we are projected into a future in which the market requires luxury products, exclusive or not, with industrial characteristics, made entirely in Italy according to the high quality standards and the traditional Italian style and good taste.

Our history

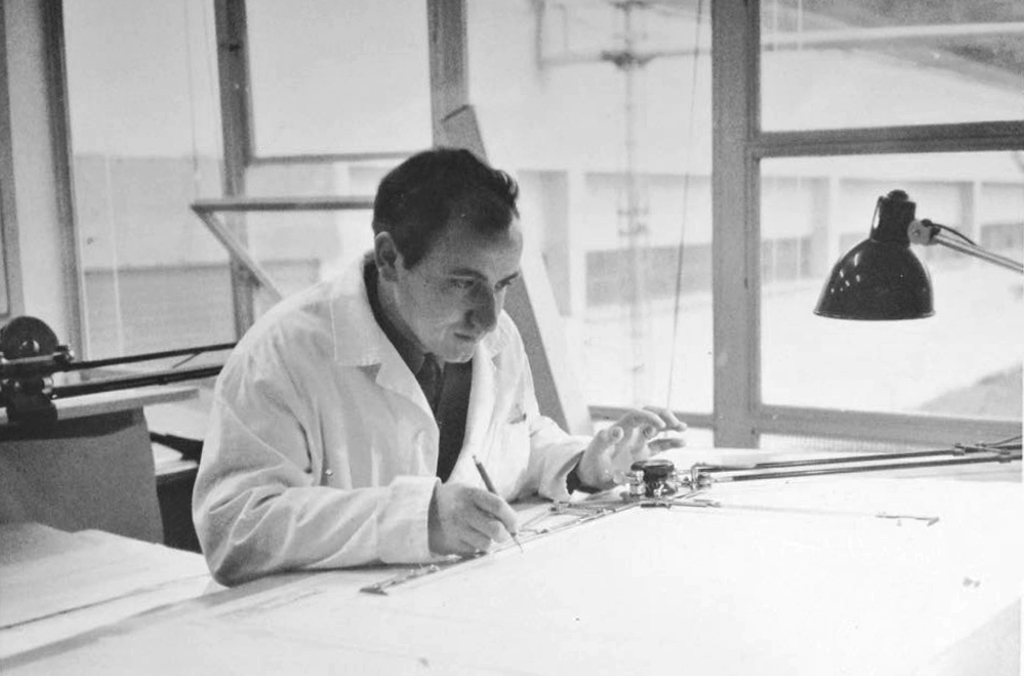

Founder and soul of GPS INOX is Franco Conti, a life spent conceiving and planning kitchens and home appliances. After a brief experience in teaching technical drawing in schools, he joined, very young, the staff of ARISTON, a leading company in the kitchen sector. These are the years of the Italian economic boom and Franco Conti starts working in the design of painted metal sheet kitchens that modernize Italian homes.

As head of the project, he is responsible for the creation of UNIBLOC ARISTON, the first example of Italian kitchen with coordination between furniture and appliances gathered under a single stainless steel top.

Over the years he continues to design kitchens and home appliances following the continuous evolution of techniques, materials and styles. In 1975 he was awarded the Gold Medal of the ARISTON Industries for the work of diversifying the range.

A great expert of steel production techniques, he left the sector of large industry and founded in the early 2000s GPS INOX to make handcrafted kitchens and kitchen accessories in stainless steel, thus continuing the family tradition dedicated to metalworking and dating at the beginning of the 1800s.

Franco Conti has always interpreted the kitchen through a contemporary and minimalist style, deeply convinced of the combination of rationality, essential lines and practical use of the kitchen. The thorough knowledge of steel processing techniques, of which he enthusiastically follows the developments, leads him to believe in the use of the most modern technologies.

Today, supported by a team of young designers, he is always a point of reference for architects and designers, of whom he interprets the creative idea, transforming it into a product with superior technical and qualitative characteristics.

Our production reality

GPS INOX: STAINLESS STEEL KITCHENS AND FURNISHINGS FOR THE KITCHEN.

GPS INOX is an Italian company for years specialized in the production of exclusive stainless steel kitchens, both indoor and outdoor and complements such as hoods, tops with sinks and welded basins, welded and supporting cooking tops, shelves, islands, tables and snacks.

The material used, stainless steel AISI 304 or 316, from the aesthetic point of view guarantees maximum elegance and shine, in perfect union with the most diverse styles of furniture, from the practical point of view, a very high resistance to corrosion and thermic shock , maximum hygiene and easy cleaning.

Quality handmade in Italy

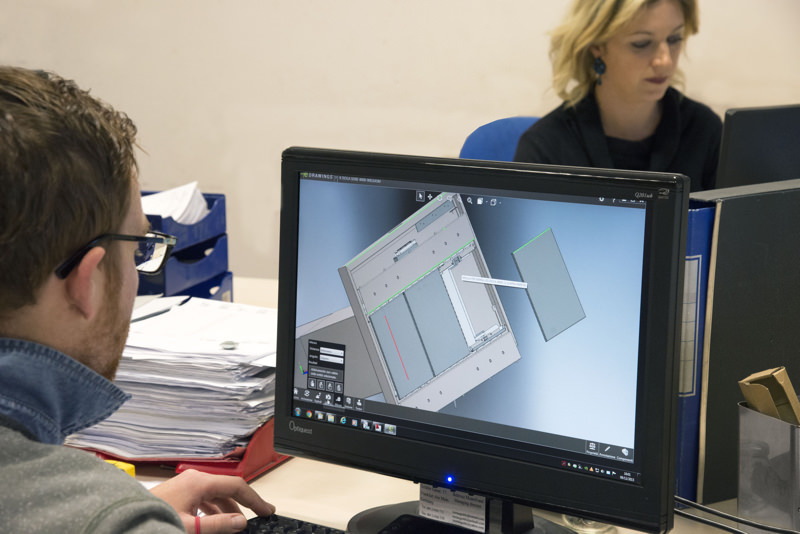

The production technique we use exclusively provides a craftsmanship that combines in our workshop the use of the latest technologies to ensure maximum quality.

Each product, whether it is a stainless steel kitchen, a hood or a countertop, is not the result of mass production , but individually made.

The first phase is that of the product design, followed by the processing steps in the workshop, that is the cutting of stainless steel sheets, bending, welding, grinding, assembly and finally quality control. All processing steps are performed by the workers without automated systems; in this way we can fully realize the customer's wishes and guarantee the highest quality both in functionality and finishes.

CUSTOMIZED PRODUCTS

Our stainless steel kitchen lines, made entirely of steel, without the use of wood materials, are characterized by rational and minimal design and provide customized solutions with high modularity, so as to meet the multiple needs of customers.The tailoring of the production makes the product unique whose sizes can be adapted to the customer's requests.

Our range of accessories for stainless steel kitchens contributes to the creation of a unique product: the customer can choose sinks, ovens and taps also of brands different from those proposed in the catalog, provided that they are compatible. Even our range hoods, characterized by rational and minimal design, provide customized solutions with high modularity, both in size, completely on the customer's choice, and accessories.

The stainless steel GPS production of steel kitchen tops offers a wide choice of sizes, height, edges and finishes. Also for the kitchen tops the customer can choose taps, basins, induction gas tops also out of catalogue.

CUSTOM-BUILT SOLUTIONS (OUT-OF-SERIES SOLUTIONS)

In addition to the lines proposed in the catalog, GPS INOX makes stainless steel kitchens and custom-tailored hoods as concerns sizes, design and customer's project.

The architect and the designer find in GPS INOX a precious partner able to shape their own ideas into stainless steel for furnishing a prestigious kitchen.

The customer who wants a unique, exclusive and luxurious stainless steel kitchen finds in GPS INOX the right company to carry it out. The packaging techniques planned by GPS INOX allow to ship the products in total safety from Italy to all over the world.

AISI 304 STAINLESS STEEL GUARANTEES A MASSIVE RESISTANCE TO CORROSION, IT IS EASY TO CLEAN, IT IS HYGIENIC AND IT COMES IN THE MOST VARIOUS SURFACE FINISHES SUCH AS:

- Tampico, semi-gloss finish with very fine brushing, recommended for the realization of worktops.

- Scotch-Bryte, less glossy finish of the Tampico, recommended for the realization of doors, sides and interiors.

- Satinized 8, Deeper and more evident effect of Scotch-Bryte suitable for the same components described above.

- Vintage, Other finishes can be made upon specific customer request.

G.P.S. INOX ALSO MAKES ON REQUEST EVERY PRODUCT ALSO IN AISI 316 STAINLESS STEEL TO GET THE MAXIMUM FROM THIS MATERIAL AND TO ENSURE A BETTER RESISTANCE TO CORROSION FROM CHLORIDE.

AISI 316 STEEL IS THE FIRST CHOICE FOR EMPLOYMENT IN SHIP CARPENTRY AND IN EVERY SITUATION IN WHICH THE PRODUCT CAN BE PUT AT RISK FROM CONTACT WITH HIGHLY CORROSIVE EXTERNAL AGENTS (COASTAL HOUSING).